Aerofoam® XLPE holds many advantages that differentiates the product range from other thermal insulation materials. The key features are:

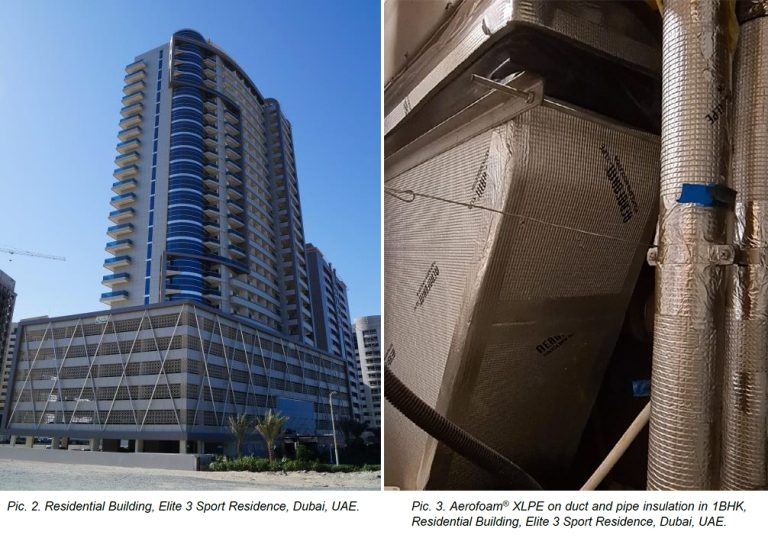

Aerofoam® XLPE is not only a perfect solution for residential buildings but also for commercial ones such as malls.

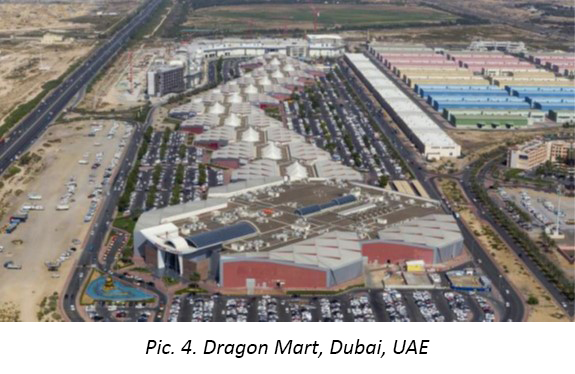

Dragon Mart, one of the largest commercial buildings in Dubai with a total floor surface of 175,000 sqm is showing in real life the benefits of Aerofoam® XLPE versus fiberglass and versus pre-insulated ducts.

Pictures attached below show current visual condition of both insulation materials installed on the duct inside the mall. It has been over 6 years from the project completion. Unfortunately, pre-insulated ducts and the ducts insulated with fiberglass material shows first signs of damages due to water penetrating its structure which leads to the need for maintenance and re-insulation works that will have to be done in the near future. Moreover, mentioned damages do not only cause bad aesthetic look of the mall interior and significant energy losses, but also exposes the employees and customers to an unhealthy environment with mold, fungus, and loose fibers.

On the other hand, Aerofoam® XLPE, which is installed in the same area of the building and exposed to the exact same conditions is still performing consistently and does not show any signs of damages nor any signs of decreased performance. It has been well maintained through the passage of time and contributes to the aesthetics of the interior of the mall.

Witnessing the fast pace of development in the 1980, Mr. Ramesh Hira, HVAC Engineer from India, founded Hira Traders LLC in the UAE, with a strategic objective of distributing HVAC utility products in the Middle East.

Hira Industries LLC P.O.Box 50673, Dubai Investments Park 2, Dubai, United Arab Emirates. Telephone: +9714-8848414 Fax: +9714-8848434

Want to get in touch? We’d love to hear from you. Here’s how you can reach us…