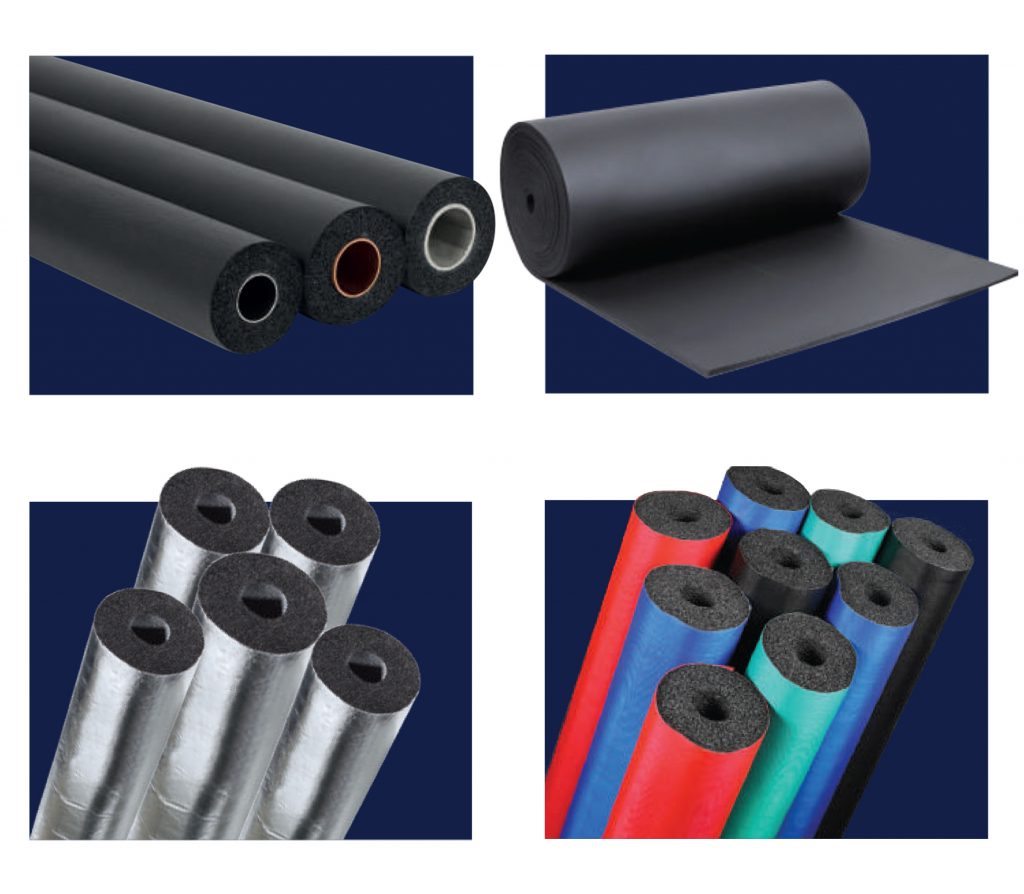

Aerofoam® NBR Rubber Insulation Tubes are closed cell elastomeric foam structure whose non-porous composition offers high thermal efficiency as well as protection from imminent condensation problems. Due to their dimensional stability, they reduce friction and reduce installation time significantly.

Aerofoam® NBR Thermal Insulation Tubes are FM approved to deliver continuous improvements in quality, technical integrity, and outstanding performance in demanding environments. Aerofoam® NBR Tubes meet the strictest safety and fire resistance standards. Aerofoam® NBR FM approval applied on the outside of non-combustible pipes or ducts enhances customer confidence in the brand further.

Not only are they environment friendly but they also don’t pose any harm to human health as they have zero Ozone Depletion Potential (ODP), Global Warming Potential (GWP) of less than 5 and a low Volatile Organic Compound (VOC) of less than 0.5 µg/m2/hr in 24 hours. The elimination of ChloroFluoroCarbons (CFC) and HydroChloroFluoroCarbons (HCFC) from the production process while complying with LEED requirements make Aerofoam® NBR Nitrile Flexible Elastomeric Tubes ideal for use in projects that need optimal air conditioning, refrigeration, chilled water pipes and hot water pipes thermal insulation.

In order to install Aerofoam® Flexible Elastomeric Foam Tubes in a professional manner, please drop an email at enquiry@rhira.com to receive the installation handbook.

| Fire rated “CLASS 0” as per BS 476 parts 6 & 7 |

| Very low water vapor permeance (1.56 E-09 g/m2.s.Pa) |

| High water vapor diffusion factor (µ> 17,000) |

| Very low water absorption rate (0.06% by volume) |

| Wide temperature range (from -80 ˚C to +110 ˚C) |

| Antibacterial & antifungal |

| Environmental friendly – ODP = 0 and GWP < 5 |

| Very low VOC emission level ( < 0.5 µg/m2/hr in 24 hours) |

| Sound absorption properties |

| Perfect fit to most of the pipe sizes |

| Easy and fast to install |

Witnessing the fast pace of development in the 1980, Mr. Ramesh Hira, HVAC Engineer from India, founded Hira Traders LLC in the UAE, with a strategic objective of distributing HVAC utility products in the Middle East.

Hira Industries LLC P.O.Box 50673, Dubai Investments Park 2, Dubai, United Arab Emirates. Telephone: +9714-8848414 Fax: +9714-8848434

Want to get in touch? We’d love to hear from you. Here’s how you can reach us…